Products

Heat-resistant UV Tape

When selecting heat resistance tape as temporary mask or carrier, the PI tape (with silicone or acrylic adhesive) is most common choice. However, the PI tape’s The adhesive strength will rise up after heating. It will increase the difficulty for P&P when the product is thin, small, and fragile.

In response to the above situation, we have developed UV tape with high temperature resistance characteristic, which can be widely used to evaluate high-temperature processes in semiconductors and various industries.

- Max. Working temp. 220~260C

- Without residue after temp. on wafer, glass and SUS material.

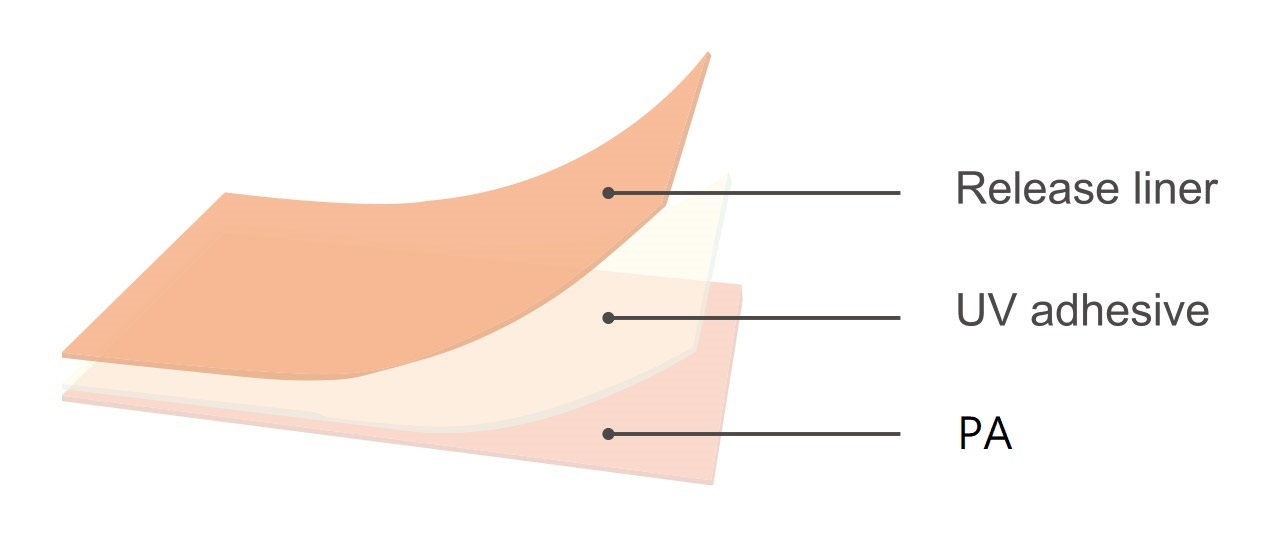

Product Structure

Product Spec

| Appearance/Surface | Transparent / Flat | ||

| Thickness (without liner) (um) | 60 | ||

| Adhesive strength (N/25 mm) | 25 ℃ / RT | 4.9 / 0.09 (SUS) | |

| 4.8 / 0.08 (GLASS) | |||

| 220 ℃ / 30min | 9.17 / 0.25 (SUS) | ||

| 7.99 / 0.24 (GLASS) | |||

| 260 ℃ / 5min | 8.7 / 0.06 (SUS) | ||

| 7.9 / 0.04 (GLASS) | |||

| **The data is before UV / after UV** | |||

Related Products

Customized Products

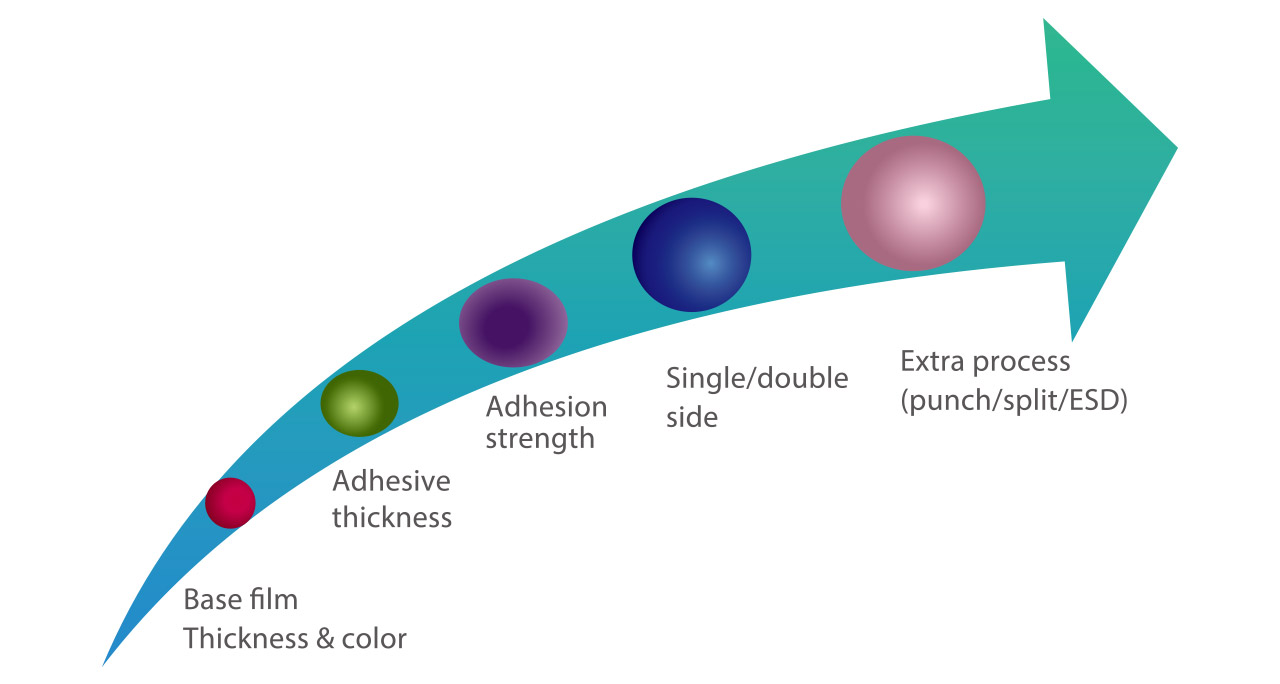

Customized Product Spec

Tape customization specifications

| Product | Adhesive thickness | Base Film | Extra Process | Adhesion Strength |

| PI Tape | 8um~120um | PI 12.5um~150um | Punch/split/ESD | 5g~2,000g |

| UV Tape | *8um~80um(~400um) | PO 80um/150um PET 25um~100um | 300g~2,000g | |

| Thermal release tape | 40um~60um | PET/PI 25um/50um/100um | Punch /split/ESD | 100g~600g |

Non-tape customization specifications

| Heterogeneous Integration | Thickness | Remark |

| DAF | 10um~120um | *under development |

| Laser Debond material | 10um~50um / 0.5um~1.5um | Film/Liquid |